With the development of 5G technology, many industries have changed.

Miners no longer need to take risks to work underground, tower crane drivers no longer need to climb towers to work in the air, and remote control provides workers with a safety guarantee; a patient boarding an ambulance is equivalent to entering a hospital, and can be completed without leaving home after recovery Medical insurance reimbursement, 5G smart medical care brings more convenience to patients.

In the intelligent transformation of Ningbo Port, China Mobile is the general integrator of the project, taking the lead in completing the intelligent gantry crane with a delay of 7 milliseconds, the unmanned 5G truck, the tally system that automatically identifies the damage of the box, and so on. Improve the operational efficiency of the port, change the way dockers work, and enter the office area to operate remotely!

5G base station for port construction

1. Intelligent gantry crane with 7ms delay

The traditional quay cranes and gantry cranes are all workers on site, and the environment is small and harsh, which tests the eyesight and experience of the workers.

Although wired transmission is fast, complex cables cannot be matched with moving objects, which can easily cause a chaotic on-site environment. The traditional 4G technology has a delay of about 0.1 seconds, and there are major safety hazards for the operation of heavy machinery. The 5G theoretical air interface delay can reach 0.01 seconds, which is faster than human response.

Nowadays, cameras are installed in key parts of the front end of quay cranes and gantry cranes. The driver can directly operate large machinery such as quay cranes and gantry cranes from the console in the background. The delay is only 7 milliseconds, and the hoisting process can be precisely controlled. The traditional manual method has a more comprehensive view, significantly improves the operation efficiency, and improves the safety of the whole process.

2. Unmanned 5G trucks

At present, the smart port solution has achieved fully unmanned trucks. The AGV unmanned trucks in the picture below have been clustered in large-scale operation in some port areas of Shanghai, Ningbo, Xiamen and other ports. In the relatively closed environment of the port area, based on 5G and RTK differential base stations, precise positioning can be achieved, and the highest positioning accuracy can be achieved at the dynamic centimeter level, which further improves the operational safety of unmanned trucks.

Unmanned 5G trucks cooperate with the operation of small cranes

In addition to the high-speed and low-latency characteristics of 5G, the larger capacity also enables autonomous vehicles in ports to operate in groups.

Compared with human drivers, unmanned 5G trucks can also accumulate a large amount of operating data, which can be aggregated to the management platform in the background. Improve the operational efficiency of the port.

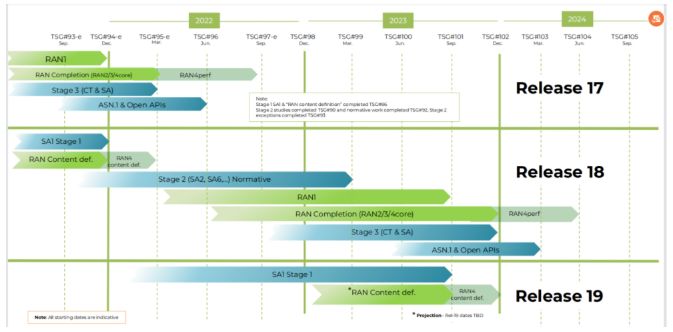

The construction of unmanned driving in a closed environment is relatively simple, but in the future, mass production of high-level unmanned vehicles on urban roads will also require 5G technology. However, the communication protocol version R18 for 5G for autonomous driving has not yet been fully determined.

By the end of 2023, the communication technology of large-scale high-level autonomous vehicles will be fully ready. If other technologies such as high-precision maps, lidar, and vehicle-road collaboration are also mature at the same time, mass production of high-level autonomous vehicles will be possible. will come.

3. Tally system for automatic identification of box damage

The traditional tally work method of the port requires the tally staff to stand at the front of the terminal all the year round, testing the physical strength, eyesight and endurance of the tally staff. The busy collection trucks and containers moving back and forth at the front of the terminal also increase the workload of tally operations. Security Risk.

Based on artificial intelligence image recognition technology, it can automatically identify the container number, box type, container position, lead seal and dangerous mark, and automatically compare and confirm the loading and unloading plan data in the system, automatically generate the ship stowage map, and also detect the damage of the container. Real-time collection and post-tracing of the images of the box and the lead seal of the box to ensure the smooth completion of a complete tally operation.

As a network infrastructure, 5G is empowering thousands of industries, far beyond what consumers can see. However, for the B-end market, the degree of customization is high, and it takes time to iterate products and solutions. In the future, all walks of life can seize the opportunity of 5G to upgrade their business.