In the electronic components industry, procurement is no longer just about securing competitive pricing and stable lead times. As supply chains become more global and fragmented, quality assurance (QA) in the procurement cycle has become a decisive factor influencing product reliability, compliance, and long-term customer trust. A single quality failure at the sourcing stage can result in production delays, warranty claims, or even product recalls.

This article outlines a practical and scalable approach to building a quality assurance process within the procurement cycle, specifically tailored for electronic components distributors and manufacturers.

1. Define Quality Requirements Before Sourcing

A strong QA process starts with clarity. Before engaging suppliers or placing orders, procurement teams must clearly define what "quality" means for each component category.

This includes:

Electrical and mechanical specifications

Approved manufacturers and part number revisions

Compliance requirements such as RoHS, REACH, or customer-specific standards

Packaging, labeling, and traceability expectations

Well-documented requirements reduce ambiguity and prevent disputes later in the process. More importantly, they ensure that procurement, engineering, and quality teams are aligned from the start.

2. Implement Structured Supplier Qualification

Supplier selection is the first real quality gate in the procurement cycle. A reliable supplier qualification process should go beyond price comparison and availability.

Key qualification criteria may include:

Quality management system certifications (e.g., ISO 9001)

Historical performance data and market reputation

Financial stability and supply continuity capability

Documentation transparency and responsiveness

For critical or high-risk components, on-site audits or third-party assessments can provide deeper insight into a supplier’s actual quality control capabilities. Establishing an approved supplier list (ASL) helps standardize sourcing decisions and reduces quality variability.

3. Apply Risk-Based Procurement Controls

Not all components carry the same level of quality risk. A mature QA process applies risk-based controls, focusing resources where they matter most.

Examples include:

Enhanced inspection for obsolete or EOL components

Additional verification for non-authorized or spot-market sourcing

Tighter controls for parts used in safety-critical or high-reliability applications

By classifying components and suppliers according to risk, procurement teams can balance quality assurance costs with operational efficiency.

4. Strengthen Incoming Inspection and Verification

Incoming inspection is a critical checkpoint where quality issues can still be contained before affecting inventory or production.

A comprehensive incoming QA process may include:

Visual inspection of packaging, labels, and part markings

Verification of part numbers, quantities, and date codes

Electrical or functional testing for selected components

Documentation checks, including CoC and test reports

For high-volume items, statistical sampling methods can be applied to maintain efficiency without compromising control.

5. Ensure Traceability and Controlled Storage

Quality assurance does not end once components pass inspection. Maintaining full traceability throughout storage and distribution is essential for both quality control and risk management.

Best practices include:

Lot and date-code tracking

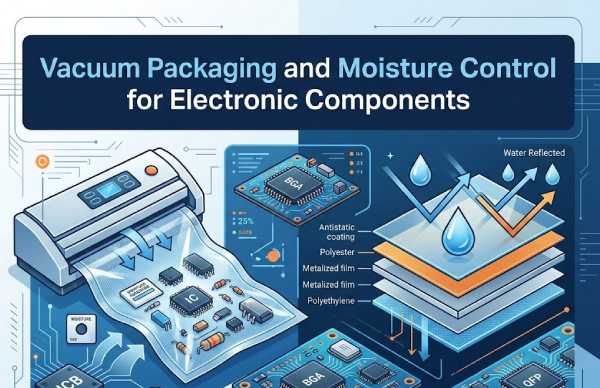

Controlled storage conditions for temperature- and moisture-sensitive components

FIFO (First In, First Out) inventory management

Clear segregation of inspected, pending, and non-conforming materials

Effective traceability enables fast root-cause analysis and targeted corrective actions if quality issues arise later.

6. Monitor Supplier Performance Continuously

Supplier quality should be evaluated as an ongoing process, not a one-time approval. Establishing measurable supplier performance indicators allows procurement teams to identify trends and address issues proactively.

Common KPIs include:

Defect rates and return frequency

On-time delivery performance

Responsiveness to quality issues

Accuracy and completeness of documentation

Regular performance reviews create accountability and encourage suppliers to continuously improve their processes.

7. Close the Loop with Corrective and Preventive Actions

Even with strong controls, quality issues may still occur. What differentiates a mature QA system is how effectively it responds.

A structured corrective action process should:

Identify root causes, not just symptoms

Define clear corrective and preventive measures

Track implementation and effectiveness over time

Lessons learned should feed back into supplier qualification criteria, inspection plans, and procurement strategies, creating a continuous improvement loop.

Conclusion

Building a quality assurance process in the procurement cycle is not a one-size-fits-all exercise. It requires clear standards, disciplined execution, and continuous evaluation. For electronic components distributors and manufacturers, procurement QA is a strategic capability that directly impacts product quality, customer confidence, and business sustainability.

By embedding quality assurance into every procurement stage—from supplier selection to incoming inspection and performance monitoring—organizations can significantly reduce risk, improve supply chain resilience, and create long-term value in an increasingly complex market.