Electrostatic discharge (ESD) and moisture-related failures are persistent risks in electronics manufacturing and distribution. As supply chains become more globally distributed and rely on multi-stage handling, the ability to control ESD and moisture sensitivity levels (MSL) at each step is directly tied to product reliability, cost, and customer satisfaction. Effective control is not just a technical requirement; it is a business strategy that reduces scrap, rework, delays, and warranty exposure.

Understanding ESD and Moisture Sensitivity Risks

ESD is a sudden transfer of static electricity that can damage or weaken semiconductor devices. Many failures caused by ESD are latent defects, invisible during inspection but prone to early-life breakdown once the product is deployed. Moisture sensitivity, on the other hand, affects packages that absorb moisture during storage or handling. During reflow soldering, absorbed moisture expands rapidly and may cause delamination, popcorn cracking, or internal damage.

Both risks are often underestimated because failures do not necessarily occur immediately. Instead, they silently erode long-term reliability, especially in sectors like automotive, medical, aerospace, and industrial electronics.

Standardizing Classification and Data Visibility

Supply chain control begins with consistent classification. Every component handled by procurement, warehousing, or production should have ESD and MSL ratings defined according to widely accepted industry standards. Recording these parameters in ERP systems enables traceability and ensures that storage, handling, and reflow processes follow known limits.

Data availability is especially critical in distributed supply chains where parts transfer between multiple partners. When components move with incomplete or incorrect information, each transfer event introduces new risk.

Inbound Inspection and Packaging Verification

Many ESD or moisture failures originate long before assembly — they originate at receiving. Quality teams should inspect incoming shipments for ESD-safe packaging, humidity barrier bags, desiccants, and humidity indicator cards. Moisture-sensitive components lacking proper packaging should be quarantined and evaluated before release.

A controlled reconditioning process, including baking and repackaging, can recover parts in some cases. However, this must be documented, timed, and aligned to the component’s MSL classification. Organizations often underestimate how small packaging deviations can create large downstream failures.

Warehouse Controls: Managing Humidity and ESD Together

Moisture-sensitive materials require controlled storage environments, typically using dry cabinets, nitrogen storage, or humidity-controlled warehouses. Real-time humidity monitoring, alarm thresholds, and logging should be standard practice.

For ESD-sensitive products, warehouses must implement grounded shelving, ESD flooring, conductive containers, dedicated ESD workstations, and personnel grounding systems.

Importantly, moisture and ESD controls must be integrated, not treated as independent programs. A warehouse that protects from ESD but exposes devices to excess humidity still fails to mitigate risk.

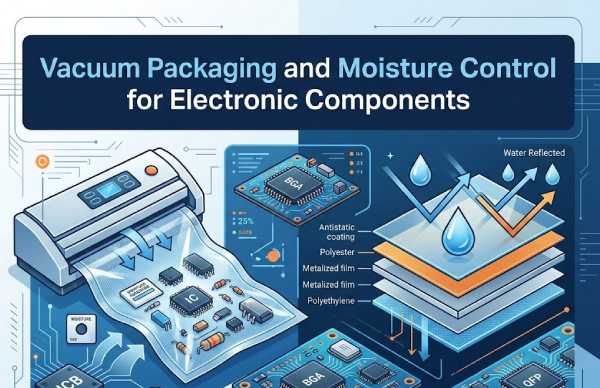

Transit and Packaging Requirements

Packaging must withstand shipping environments that include vibration, temperature swings, humidity, and uncontrolled ESD exposure. Outer containers should prevent mechanical stress, while inner packaging protects sensitive devices.

Labels indicating MSL class, exposure limits, and sealing dates support traceability. Serial numbers or barcodes further enhance tracking and accountability. A well-structured supply agreement should clarify who is responsible for mitigation, reconditioning, or replacement when packaging is compromised.

Shop Floor Controls and Human Factors

Once components reach manufacturing, both environmental controls and human behavior play a role. A comprehensive ESD program includes wrist straps, grounding audits, ionization, conductive tools, and regular compliance monitoring.

For moisture-sensitive parts, strict control of floor-life is necessary. When components leave dry storage, exposure time should be tracked, and expired material should be automatically removed from production unless properly baked.

The most sophisticated systems fail when operators are not trained or when rules rely on manual enforcement. Digital tracking and automated checkpoints reduce dependence on memory and supervision.

Measuring Performance and Continuous Improvement

Data-driven feedback is essential to long-term control. Useful metrics include:

Incoming packaging nonconformance rate

ESD incident logs

Rework hours related to soldering defects

First-pass yield per component category

Cost impact of field returns or scrap

When metrics reveal systemic issues, supplier scorecards, training programs, or inventory strategies should be updated accordingly.

Leading organizations treat ESD and MSL control as dynamic programs requiring periodic audits, technology updates, and performance incentives.

Strategic Value of ESD and Moisture Control

Investing in control systems often appears costly in the short-term, yet organizations consistently report reductions in rework, scrap, downtime, and warranty claims. More importantly, strong protection systems build customer trust. In industries where reliability translates directly into safety, failure-prevention is not optional.

Conclusion

ESD and moisture sensitivity control is not just a factory-floor issue; it is a supply-chain discipline that spans procurement, logistics, warehousing, assembly, and quality assurance. Companies that standardize classification, enforce packaging standards, integrate environmental controls, and use data for continuous improvement transform operational risk into competitive advantage.

As electronics become smaller, more integrated, and more mission-critical, the organizations that prioritize proactive control will lead the industry in reliability and resilience.