A PCB package has many interconnections that make it an integral part of electronics. These many interconnections create deep complexities that require specialized examination. This shows the importance of automated X-ray PCB inspection.

First, let’s dive into what X-ray PCB inspection is.

What is X-ray Printed Circuit Board (PCB) Inspection?

Across fields, from aerospace to marine to medical manufacturing, X-ray PCB inspection is used to detect hidden defects in solder and other manufacturing errors that cannot be detected with ordinary optical inspection. Using X-ray to identify errors, whether minor or major, X-ray PCB inspection does not damage the board being inspected.

Factors that complicate PCB inspection include:

Surface mount technology

Surface mount technology results in smaller packages and leads. These make the PCB denser, with many components hidden between the layers.

Component size

Miniaturization of circuit board components is a trend in electronics manufacturing today. Currently, there is a strong demand for denser boards, which puts pressure on the production of more PCB assemblies.

Placement of components

There is a pressing need for smaller layered devices that save space and maximize functionality. Therefore, many components and solder joints are placed on the inner layers of electronic products.

These complex requirements and designs make it difficult for common inspection methods such as ultrasonic, optical and thermal imaging to provide detailed fault-finding images. To overcome these challenges, X-rays for PCB inspection are used.

How is X-ray used for PCB inspection?

X-rays are essentially high-energy electromagnetic radiation that have long been used in medicine. They are now commonly used in the field of inspection to provide a clear glimpse into the internal structure of components. X-rays are used in the inspection industry due to their efficiency and reliability.

Typically, X-ray photons have energies between 0.1 and 1,000 kV and wavelengths between 0.1 and 10 nm.

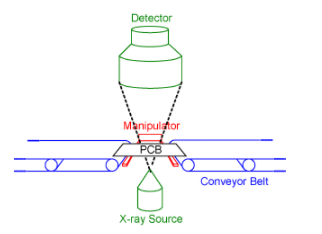

For inspection using X-rays, the component being viewed (in this case a PCB assembly) is placed between the inspection medium and the X-ray machine.

The penetration of X-rays through the part being viewed depends on the energy of the X-rays as well as the density and nuclear charge of the object being inspected. Fortunately, x-ray machines can be adjusted to take all of these factors into account.

Inspection media works by generating a visual image of the x-ray material (PCB assembly) either digitally or through traditional radiographic film.

While traditional radiology film has been used for a long time, its digital counterpart offers additional advantages. For example, Digital media has higher contrast, higher resolution, and more flexibility, reducing the waste and time of developing traditional radiographic films. Interestingly, many X-ray machines have a clamp that holds and allows the operation of components to be viewed from multiple angles.

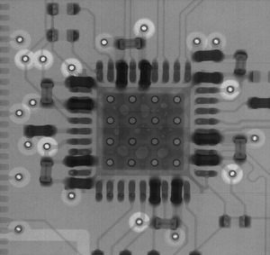

When the X-rays pass through the PCB element, the different densities of the element reduce the X-rays by different amounts. Light and dark spots are produced on the detection medium.

Let's take a step further and show how X-ray inspection of PCBs works.Typically, the X-ray source is placed below the lead-lined chamber and the digital media detector is placed directly above it. Conveyor belt into the PCB components lead lining chamber and place it between the detector and the source of the manipulator.

Once this arrangement is achieved, the X-ray system can perform a detailed inspection of the PCB assembly by operating accordingly.

X-ray PCB Inspection Technology

There are two main techniques used in X-ray PCB inspection: 2D systems and 3D systems.

Let's see what these technologies require.

2D X-ray system

The system generates X-rays at a single point, passing through the PCB assembly. This way, the system generates a 2D image on the media detector. Note that 2D systems can be operated either online or offline.

Additionally, 2D X-ray systems display 2D images of the entire assembly from both sides of the PCB.

3D X-ray system

If you have complex double-sided PCBs, a 3D X-ray inspection system is the best choice. In this system, the media detector performs a 180-degree circular motion, creating images of various cross-sections.

This means you can perform a more detailed and precise analysis of the inspected component.

Advantages of X-ray Inspection of PCBs

Rapid feedback in the early stages of product development enables manufacturers to take corrective actions to improve product quality and encourage a positive brand name.

Designers will have the opportunity to not build on defective parts, saving unnecessary costs.

X ray make inspector can recognize printed circuit boards, a series of potential problems, and recommend specific corrective actions.

For more information, visit perceptive-ic.com.