ESD, EMI, EMC design is a common problem encountered by electronic engineers in the design, and electromagnetic compatibility (EMC) means that a device or system operates in compliance with the requirements in its electromagnetic environment and does not cause intolerable damage to any equipment in its environment.

Capability of electromagnetic interference.

1.The purpose of electromagnetic compatibility design is to enable electronic equipment or systems to work normally in the expected electromagnetic environment without performance degradation or failure, and not to constitute electromagnetic interference to anything in the electromagnetic environment, so as to achieve electromagnetic compatibility.

2.Among them, EMI focuses on the test requirements and the interference between adjacent equipment.

EMC/EMI not only involves the three mandatory certifications, but also has a deep relationship with the radiation simulation principle of the power plane.

The automotive products in many modern high-quality solutions have excellent anti-electromagnetic interference (EMC) performance, can meet EMI CISPR Class 5 automotive electromagnetic interference requirements, and have excellent ESD capabilities and excellent anti-electromagnetic interference (EMC) performance.

EMC (Electromagnetic Compatibility) specifically refers to the ability of a device or system to operate in compliance with the requirements in its electromagnetic environment without causing unbearable electromagnetic interference to any device in its environment.

Designers can get inspiration from the commonality and connection between water flow and current, that is, the common mode current lies in "sparseness" , which is the core idea of product EMC design. If the design is only based on experience, not only the cost is high, but also the stability is poor, and the existing design methods can no longer meet the needs of product EMC design and development. Additionally, measuring the amount of EMI generated by electrical systems inside equipment is another process known as emissions testing.

As we all know, the electromagnetic compatibility (EMC) design of products is roughly classified into three types, namely shielding , filtering, and grounding. The EMI-EMC design of communication switching power supply generally adopts pulse width modulation (PWM) technology, which is characterized by high frequency, high efficiency, high power density and high reliability.

Master the use of components for EMC design rectification: capacitors, magnetic beads, filters, inductors, transient suppression devices, etc.

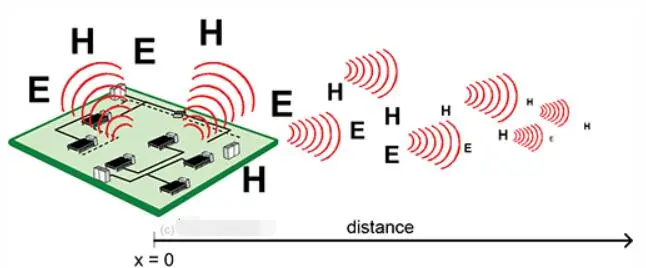

From the point of view of system equipment EMC/EMI design, dealing with EMC/EMI problems in the PCB design stage of equipment is the most effective and cheapest way to make system equipment meet the EMC standard .

· From the perspective of EMC/EMI design in terms of structure, the purpose of electromagnetic shielding is twofold: one is to limit the internal radiated electromagnetic energy beyond a certain area; the other is to prevent external radiation from entering a certain area.

· On the other hand, according to the different needs of design managers and engineers, continuously providing the most advanced and in-depth EMC, EMI design technology and application is the development direction that product design should establish today; meeting EMC requirements is not only to meet relevant specifications, It is the need to realize the high performance of electronic equipment.