Over the past few years, artificial intelligence (AI) has played an increasingly important role in the chip development process. Since its release, Synopsys has announced that customers have taped out more than 100 chips using AI tools to increase productivity and produce significantly better chips. The company used Synopsys DSO.ai to achieve product differentiation and power, performance, and area (PPA) enhancements.

Over the past few years, artificial intelligence (AI) has played an increasingly important role in the chip development process. Since its release, Synopsys has announced that customers have taped out more than 100 chips using AI tools to increase productivity and produce significantly better chips. The company used Synopsys DSO.ai to achieve product differentiation and power, performance, and area (PPA) enhancements.

This is where AI-driven automation can help address the growing need for differentiated products while freeing design teams to focus on the innovation pipeline (Synopsys' DSO.ai - Design Space Optimization AI - is a solution for AI-driven chip design ).

Using reinforcement learning techniques to autonomously search the vast chip design space for optimal solutions, AI assistants can help engineers build better, faster, and cheaper semiconductors.

Related: The whole process of chip manufacturing

Now that AI has proven its worth in chip design—even for AI applications—where do we go from here?

At Synopsys, we see the clear benefits that expanding the use of AI in the chip design and verification process can bring to silicon outcomes and productivity. AI can not only solve the iterative work of chip design, but also speed up the process and help teams get to the finish line faster. By shortening design and verification cycles and reducing effort, design teams can spend more time on innovative core ideas, saving them a lot of time and money so they can focus on what they do best: innovating.

In short, artificial intelligence augments human capabilities. Humans are great at coming up with unique ideas, but those ideas are usually at the system or architectural level. To implement these ideas, engineers need EDA tools. To help accelerate implementation, Synopsys sees AI as the way forward. By integrating AI into our solutions and using them as easily and seamlessly as possible, we help engineers achieve their goals faster.

AI Everywhere: Accelerating Chip Design At Every Node

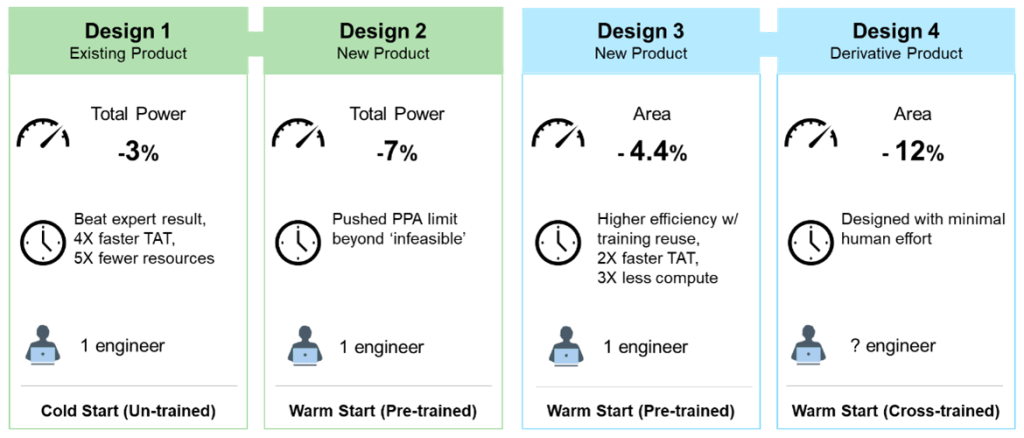

A recent customer demonstration at a Synopsys User Group (SNUG) event demonstrated the benefits of the AI-driven design solution across multiple 40nm production chips. The four designs described operate in the 5-10 million gate range at 100-200MHz—mainstream by today's standards. The customer's main goal is to reduce power and area for next-generation products with the shortest turnaround time and fewer engineering resources.

On the first design, expert engineers spent a month fine-tuning and optimizing the design, reducing power consumption by 9%. Applying Synopsys AI solutions, the design team achieved a 12% energy efficient solution in just one week. With no prior training data (cold start), the AI beat expert engineer-generated results 3% faster in a quarter of the time and using fewer resources.

(Related: What is the difference between scan and bist in chip design and testing?)

Because DSO.ai has a learning system that continuously trains and updates its machine learning models, reuse across designs and projects helps organizations scale to AI-level productivity. For the second design, the customer applied this learning system (warm boot) with different modifications throughout the design cycle, achieving a 7% power reduction, a goal previously considered unattainable.

Encouraged by these positive results, the AI solution was used to help optimize the area of two additional production designs. In the first term, the customer saved 4.4% in area. Going a step further, the knowledge learned from this design is re-used for subsequent derivative designs. This cross-training resulted in a 12% reduction in area with almost no human intervention—unleashing the true AI-powered chip design.

Conclusion:

In this article, we discuss the different mainstream AI chips, their evolution, and how they are proving beneficial for enhancing today's technology. Each of them is different from the other and has its advantages. However, they all have the potential to revolutionize technology. By automating repetitive tasks, solutions like Synopsys DSO.ai enable the semiconductor industry to forge a productive new path to continuous innovation that brings smarter products to us all.