The ten most commonly used sensors:

2D vision sensor

It's a smart camera that can do a number of things, including detecting moving objects and finding parts on a conveyor belt. The robot can adjust its actions appropriately based on the information it receives.

3D vision sensor

A 3D vision system can use two cameras from different angles or a laser scanner to perform its function and can detect three dimensions of an object. For example, part picking and placement using 3D vision technology to detect objects and create 3D images. It also analyzes and chooses the best picking method.

Navigation (Positioning) Sensors

Navigation or positioning sensors approximate the position of the robot. The standard positioning sensor is GPS (Global Positioning System). Robotic receivers acquire and process signals transmitted by orbiting satellites. It uses the processed information to localize the velocity and approximate position of the robot.

Gyro sensor

Gyroscopic sensors, or gyroscopic measurements, use the principle of angular momentum to help maintain orientation. It helps to calculate the rotational speed in a specific area of the shaft.

Sound sensor

Sound sensors in robotics work like microphones and are connected to a circuit that evaluates sound amplitudes up to a certain threshold and reports the results to the robot. The noise becomes louder as the amplitude increases. A more complex application of sound sensors is speech recognition, where robots respond to user commands.

Proximity sensor

Proximity sensors in robotics detect (or "sense") nearby objects without physical contact. The amount of light an area receives can help determine the presence (or absence) of nearby objects. For robots, sensors provide a way to avoid collisions.

Infrared (IR) Transceiver: An IR LED directs an IR beam at an area of interest, detecting any light reflected from objects within that area, thereby generating an electrical signal.

Ultrasonic Sensors: These sensors generate high-frequency sound waves, and the recorded echoes indicate the presence of objects. Ultrasonic sensors can also measure distance.

Touch sensor

A touch sensor is a device that detects the touch of an object. They are found in small devices like micro switches and limit switches. The robot deploys these sensors to avoid obstacles. Sensors indicate whether the robot can back up, stop, start, turn, etc. when it encounters an obstacle.

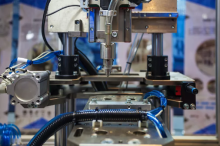

Force sensor

Force sensors calculate the forces required for various robot functions such as material management, machine handling or material management. Sensors improve the assembly process for troubleshooting, give the robotic arm a feel for completing assembly tasks, and internal state sensors measure end effectors.

Accelerometer

The accelerometer measures the acceleration and inclination of the robot. Two types of forces affect the accelerometer.

Static force is the frictional force that exists between two objects. Gravity can be measured to determine how much the robot is leaning. This parameter helps to balance the robot. It can also assess whether the robot is on a flat or sloped surface.

Dynamic force is the acceleration required to move an object. A robot's velocity, or speed, can be determined by measuring its dynamic forces using an accelerometer.

Temperature sensor

Temperature sensors measure heat or temperature changes in the surrounding environment. There are various ways to measure temperature, such as using materials that change electrical resistance or certain materials that produce a voltage change across a semiconductor junction when heated or cooled.