The difference between M2M networks and Internet of Things (IoT) connectivity

Automated design prompts and modulates higher-level operations is a relatively new capability that depends on both M2M and iot technologies. For an in-depth look at the differences between these systems, read the Digi-Key article "The Differences between iot and M2M Communication and their Design".

M2M technology is good at monitoring and controlling individual (and somewhat isolated) functions. This technology is increasingly implemented through the adoption of embedded devices for cellular communication. Many M2M installations are native and use one or two sources of information. For example, a consumer-level M2M setup might include a thermostat and camera that continuously stream data to a wearable device or smartphone -- perhaps to prompt a human operator to make adjustments. The only data points are from those sensor pieces.

Iot means fully integrated and interconnected devices (often involving machine actuation and feedback) to support complex systems, information sources, or collaborative operations between parts of highly automated machines. As a result, the same consumption level setting (thermostat and cameras, and integrated the function of the Internet of things smart phones to communicate) will use the data points from these feedback devices (like M2M Settings), and from the Internet about the local weather forecast, crowdsourcing community data, other data of expert analysis and machine learning database, To notify the response of a human operator or some kind of networked automation device.

In an industrial setting, such iot capabilities also enable predictive maintenance and the use of big data to implement enterprise-level (business) functions. Typically, some centralized system collects partially or fully filtered machine automation and feedback data. The system analysis then generates specified parameters for further monitoring, tuning, or adjustment. Factories are increasingly using big data, sometimes supplemented by machine learning, to manage normal operations as well as problematic operations that require maintenance or other action. For example, modern natural gas pipelines transfer data from remote pumping stations to a central database that can be accessed by personnel in control and command centers; In some cases, these personnel may be located on completely different continents.

Hardware types that support M2M functions

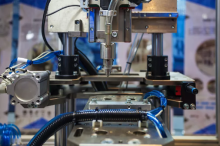

Sensors, actuators, and embedded logic devices are the main hardware types that support M2M. Sensors and actuators are typically supplied by component manufacturers and have built-in M2M connections. In contrast, embedded M2M modules are typically integrated by Oems into their own devices to perform specific tasks and functions -- often by adding cellular and other forms of connectivity to devices that might have previously worked separately. Such embedded M2M systems are particularly useful in the transportation and aerospace industries -- especially for GPS navigation systems, interlocks, and recorders and sensors on assets such as ships, aircraft, and long-haul trucks.

M2M Software: The software platform used for an M2M device depends on the mobility of the machine, the environment in which it is located, and the amount and type of data to be processed. In the case of M2M software leveraging cloud computing, it runs on hardware that communicates with remote servers. The server runs its own software and sends the information to administrators, who then process and manipulate the data. In some cases, software to support M2M networks includes software to provide a graphical user interface (GUI). Such GUIs allow human workers to access filtered system data, which is often presented as graphs, charts, and videos, rather than complex and potentially confusing text interfaces.

Domain of application of M2M network

Focus on diagnostics and maintenance applications: The M2M network supports diagnostics and maintenance, machine optimization, and application-specific controls. Because the M2M network continuously sends and receives data, it is suitable for optimizing maintenance plans for stand-alone devices in a manufacturing plant and signaling when unplanned maintenance may be required. At this point, the sensors of the connected machine can send data through the software stack in the cloud and aggregate that data to another device; Ultimately, it provides information about the maintenance of equipment or systems. For example, abnormal temperatures may indicate that the shaft needs to be re-lubricated or that parts need to be replaced due to mechanical wear.

In the airport's public and backstage areas, the M2M network collects information on temperature, vibration and gear motor lubricant levels from escalators, moving walkways and baggage handling systems. In addition, the M2M network uses sensors on airport water dispensers to monitor water flow, temperature, the opening or closing of the door, and even potential leaks.

Graphical display of machine condition: The simplest on-board M2M status indicator takes the form of an indicator light and a digital readout. But as mentioned earlier, more advanced M2M systems support GUIs to communicate machine conditions to humans in an easy-to-understand data format. In some cases, such displays are also available on machines or devices -- in small displays or even full-size HMI. In other cases, the graphical display is located in a remote location.