Scheme introduction:

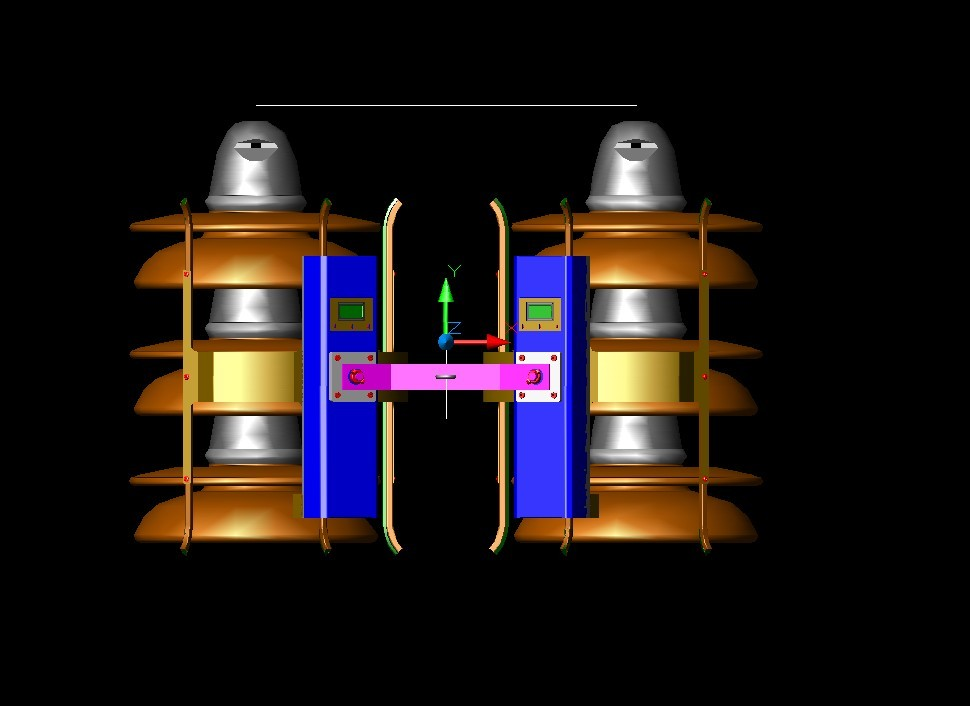

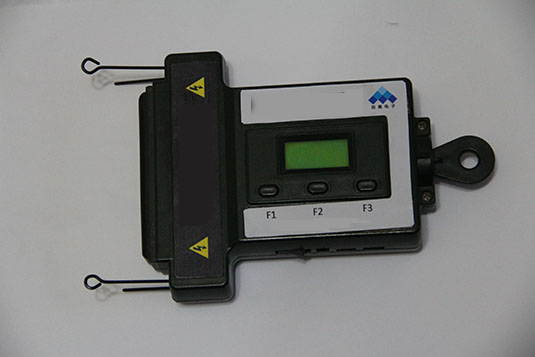

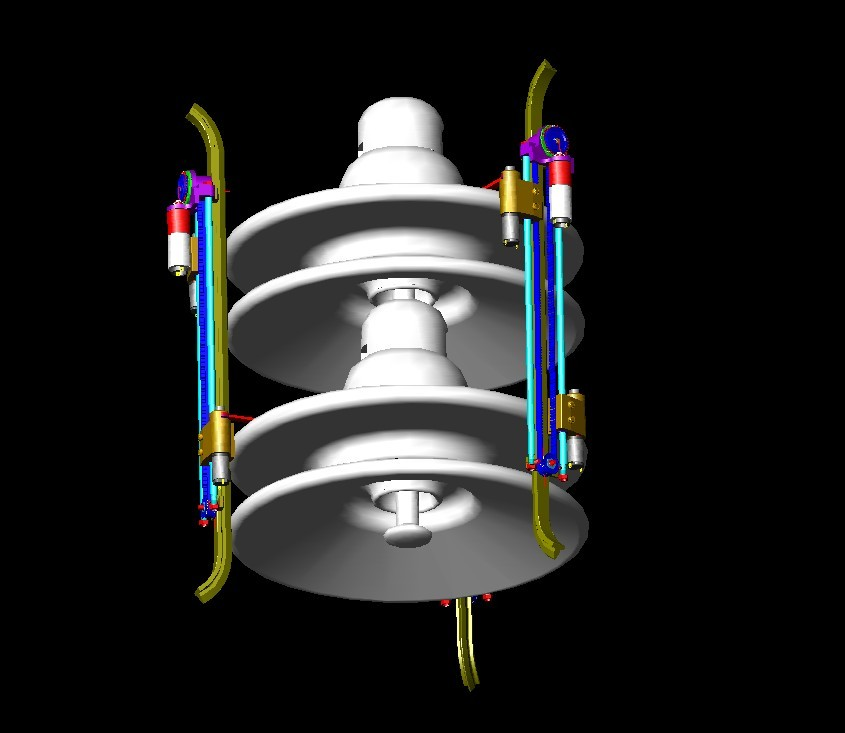

The intelligent insulator detection robot and its detection method have been independently developed for many years, applied for and obtained a number of invention and utility model patents (CN201120069946). The robot fills in the technical gap of automatic live detection of insulators on EHVDC transmission lines. This detection robot can automatically crawl along the insulator string, perform quantitative detection, automatically record, find abnormal insulators and automatically alarm. The records can be automatically imported into the upper computer analysis software, and the single point historical fault record analysis and the comprehensive analysis of the insulation condition of the high-voltage transmission line insulation system can be realized by cooperating with the high-voltage transmission line inspection system.

The detection method of the detection robot can automatically conduct quantitative detection on the insulation performance of high-voltage transmission line insulators under the live condition. This method can not only conduct live quantitative detection on insulators of 220KV and above high-voltage and ultra-high voltage AC transmission lines, but also conduct live quantitative detection on insulators of 1000KV DC ultra-high voltage transmission lines.

Technical features:

Compared with the commonly used insulator detection methods, such as spark fork method, small ball discharge method and hand-held intelligent insulator detector developed in recent years, the intelligent insulator detection robot has incomparable advantages in technical applicability, manual operation convenience and safety.

First of all, the robot does not need to manually lift the pole for a long time during the detection, which greatly reduces the work intensity of the detection personnel, saves time and labor, avoids the missed detection and personal safety problems caused by manually lifting the pole directly to detect insulators, and has high detection efficiency. During detection, workers only need to use a special arm to place the detection robot at one end of the insulator string, and control it through the remote controller to make it crawl along the insulator string from top to bottom, and then crawl back and forth from bottom to top once to complete the detection task. Parallel horizontal strings can detect two strings at the same time. The detection method is convenient, fast, safe and reliable.

Secondly, the scope of detection is wide. This detection method is applicable to the live quantitative detection of insulators for conventional 220KV high-voltage transmission lines, especially for ultrahigh voltage and 1000KV ultrahigh voltage DC transmission lines above 500KV. The problem that the traditional method and the modern intelligent insulator detector can not be used to detect the electrification of the 500KV and above EHV transmission lines is completely solved. The detection method directly fills the technical gap that the HVDC transmission lines can not be quantitatively detected with electrification.

Performance parameters:

Industry classification: test equipment

Delivery form: complete machine

Performance parameters: detection mode: live online, measurement range: 10KV~1000KV

Application scenario: live monitoring of high voltage and ultra-high voltage power grids