The evolving role of PLCS in IIoT

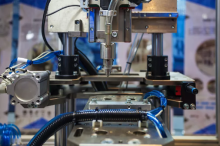

As the intermediate equipment in the factory automation system, PLC has been providing sensors, actuators and other equipment for many years to connect to the host system required multiple interfaces. To serve IIoT applications, PLC systems not only need to support a larger number of endpoints and local processing capacity, but also need to be small enough to be mounted on a single piece of equipment or in an inconspicuous location in a work unit or subassembly line. This can cause developers to get bogged down in design details, considering solutions for the many interfaces needed in an industrial environment.

In many cases, this is a poor use of developer time that could be better spent providing high-level solutions for smart factories, adaptive manufacturing, predictive maintenance, and other emerging capabilities based on AI approaches. A flexible modular interface approach to sensors and actuators can reduce development time, but the interface solution must be robust enough to withstand harsh industrial environments.

Industrial interface

Typical industrial environments require a variety of interfaces to meet the communication needs of digital and analog signals between peripherals and host systems. The IO-Link industry standard has become an effective way to connect compatible end devices, as well as traditional sensors and actuators.

In a standard point-to-point IO-Link connection, the developer can connect to the IO-Link transceiver via a low-cost 3-wire or 4-wire unshielded cable terminated with a standard M12 connector using the IO-Link master station in the PLC. With its electrical interface and functional protocol, IO-Link ensures reliable communication even in harsh industrial environments with electrical noise. Io-link main components (such as Maxim Integrated MAX14819) solve the implementation complexity of IO-link electrical interface and protocol. For electrical interfaces, the MAX14819 integrates the circuitry needed to generate L+ and L-regulated power supplies, as well as the C/Q data signals required by the IO-Link standard. For the communication protocol, the device integrates the basic building blocks of the IO-Link communication approach, such as the IO-Link framer, UART, and FIFO (see "Using IO-Link transceivers to reduce power consumption, Improve Performance, and simplify Development").

To connect a sensor or actuator to the IO-Link master station in a PLC, developers can easily find compatible IO-link devices, or they can easily build their own devices using the Maxim MAX14827A transceiver