In today's electronics industry, global sourcing has become both a necessity and a challenge. Engineers and procurement teams often need to secure components from overseas markets due to shortages, long lead times, or end-of-life (EOL) notices. However, risks such as counterfeit goods, mismatched packaging, and unreliable logistics are very real. To minimize these risks, buyers should approach sourcing systematically—starting with Manufacturer → Part → Application → Description → Package → Case (MPADPC). This framework keeps searches precise and ensures consistency from the very beginning.

1. Start with the Manufacturer and Authorized Channels

Every sourcing process should begin with the original component manufacturer (OCM). Identify the exact manufacturer and part number, then consult the OCM's official distributor list. Authorized distributors offer genuine parts, full traceability, and compliance with packaging standards—dramatically reducing the risk of counterfeit goods.

When authorized channels cannot meet demand—especially during allocation or after a part has been discontinued—large global distributors like Digi-Key, Mouser, Arrow, Avnet, and Future Electronics are reliable alternatives. These companies provide solid logistics, datasheet support, and clear packaging methods that help safeguard production.

2. Verify Suppliers with a Structured Checklist

If you must explore independent or overseas suppliers, verification is crucial. Use a simple but effective workflow:

Cross-check data: Confirm that the part number, date codes, and lot sizes match the OCM datasheet and package drawings.

Request documentation: Ask for certificates of conformity (CoC), traceable purchase records, and high-quality photos of labels and packaging.

Evaluate credentials: Check ISO/AS certifications, business registration, and supplier history.

Seek references: Look for testimonials or case studies from similar industries.

This process ensures you are not relying solely on price—a common trap in international sourcing.

3. Use Inspection and Testing as Safeguards

Even when documents appear correct, counterfeit or refurbished parts may slip through. To protect product integrity, set minimum inspection and test standards:

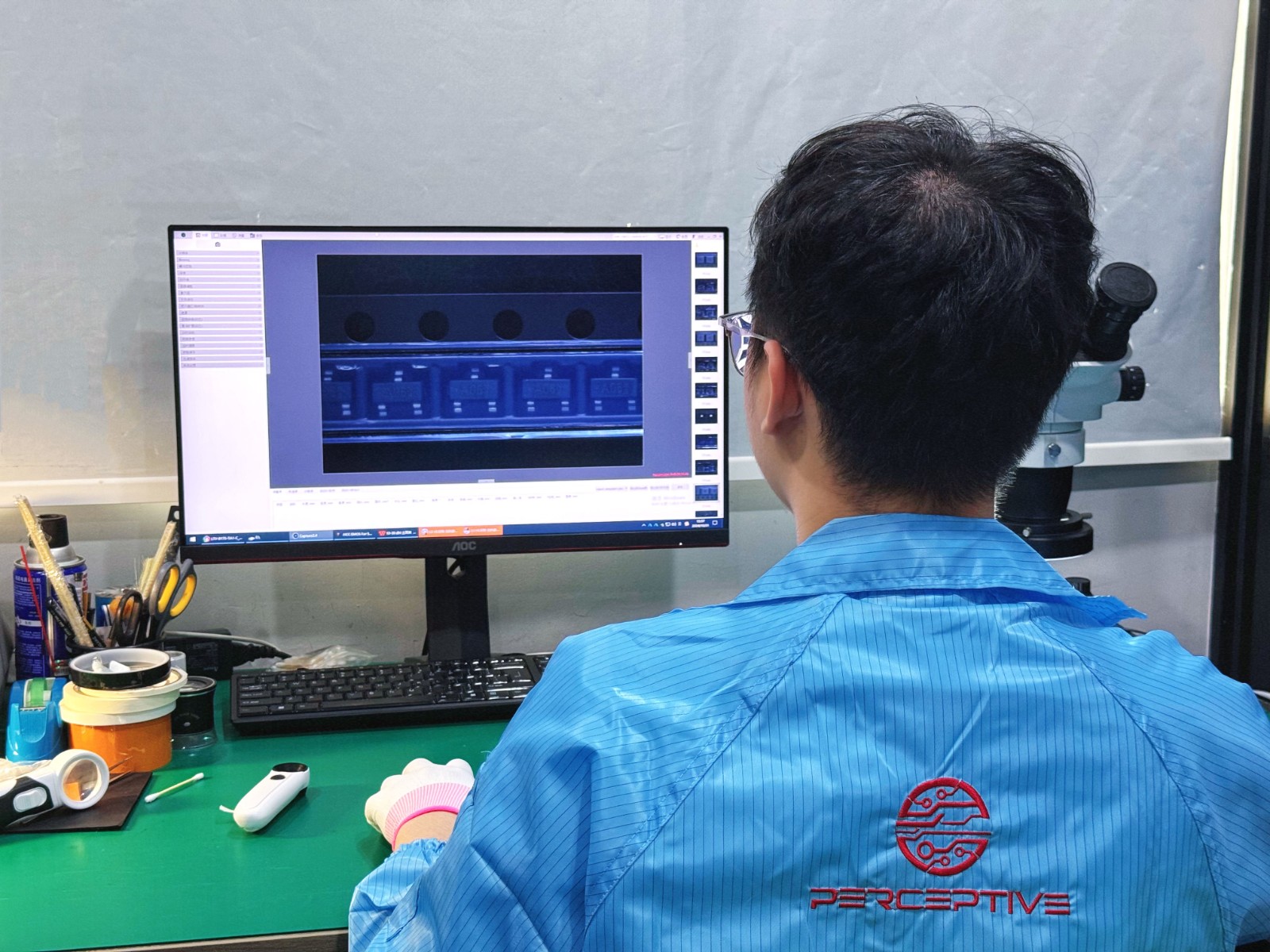

Visual inspection under magnification to check for marking irregularities, package inconsistencies, and tampering.

Electrical tests to confirm functionality against the OCM datasheet.

X-ray or destructive tests for high-reliability components in critical sectors such as aerospace, automotive, and medical devices.

By tailoring inspection depth to part criticality, companies can balance speed, cost, and risk control. Commodity passives may only require sampling, while mission-critical ICs should undergo comprehensive validation.

4. Practical Sourcing Tactics That Save Time and Cost

Several strategies can make global procurement both safer and more efficient:

Triangulate suppliers: Always compare price, lead time, and lot information from at least three vendors. Large discrepancies are red flags.

Leverage aggregator platforms: Use B2B component search engines to filter suppliers by stock, region, and quality rating.

Order samples first: For medium-risk sources, buy small trial lots before scaling to full reels or trays.

Confirm packaging requirements: Ensure components are delivered in the correct format—tape & reel, trays, or tubes. Incorrect packaging can cause assembly issues or even damage sensitive devices.

These tactics prevent costly production delays and build resilience into your supply chain.

Quick Checklist for Overseas Buyers and Engineers

Match MPADPC data with the OCM datasheet.

Prioritize authorized distributors whenever possible.

Collect supplier documentation and packaging evidence.

Define inspection and test levels by risk category.

Use samples and multiple sources to reduce exposure.

Conclusion

Reliable overseas sourcing requires a clear process: follow Manufacturer → Part → Application → Description → Package → Case, prioritize authorized distributors, and verify alternative suppliers. Perceptive Components supports engineers and procurement teams with authentic parts, traceable supply, and expert guidance—helping you reduce risk, avoid counterfeits, and keep production on schedule.