In today's electronics industry, every component counts. With growing pressure on lead times, shrinking profit margins, and increasingly complex devices, ensuring the quality of each part before shipment has never been more important. Yet, many companies still overlook or underinvest in pre-shipment inspection processes, leading to a cascade of costly issues—return handling, replacement logistics, customer dissatisfaction, and brand erosion.

A high-quality component inspection process is not just a matter of compliance—it's a strategic tool that helps businesses eliminate hidden risks, improve customer satisfaction, and avoid the avoidable: rework, returns, and resource waste.

The Hidden Costs of Post-Shipment Failures

When a defective or questionable electronic component slips through the supply chain and reaches the customer, the damage is often much greater than the cost of the part itself. Some of the typical consequences include:

Product delays due to requalification or reassembly.

Increased freight and logistics costs from return shipments and expedited replacements.

Technical support overhead, as engineering teams work to identify failure points.

Loss of customer trust, especially for OEMs that rely on consistent quality.

Environmental waste, when unusable components are discarded or products are scrapped.

All of these challenges can be significantly mitigated with a preventive inspection process at the source—before the product ever leaves the warehouse.

Inspection as a Strategic Process, Not Just a Checkbox

Many suppliers treat inspections as a procedural formality or final "checkbox" before shipment. But in a high-performance quality system, inspection is an active, layered defense mechanism. It involves:

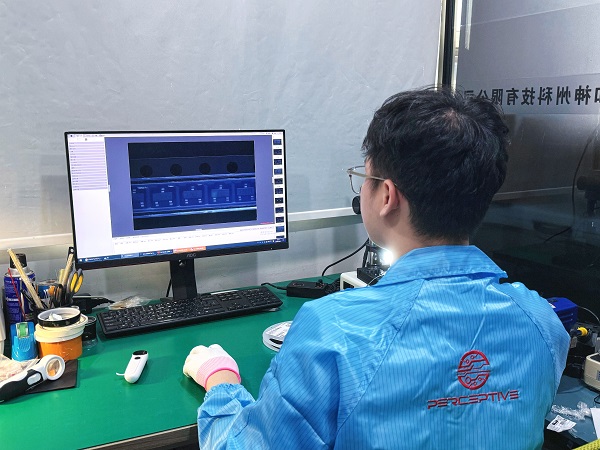

Visual inspections under magnification to detect scratches, bent leads, and unusual markings.

X-ray analysis to verify internal die structure and bonding consistency.

Solderability testing to ensure long-term reliability in actual assembly environments.

Electrical testing, both functional and parametric, to verify specifications.

Decapsulation and die inspection for high-risk or mission-critical parts.

Each of these tests serves to catch a different type of defect—be it counterfeit, refurbished, ESD-damaged, or out-of-specification—and collectively they ensure that no red flags go unnoticed.

Preventing Waste: A Win for Both Business and Environment

Preventing a defective component from being shipped means saving more than just replacement costs. It prevents wasteful double-handling of materials, unnecessary fuel consumption from logistics, and often irreversible environmental impact.

In the broader context of sustainability and ESG (Environmental, Social, and Governance) performance, companies that proactively reduce product returns and waste align themselves with global regulatory trends and consumer expectations. A smarter inspection process is not just a quality issue—it's a sustainability advantage.

Feedback Loop: Inspection as a Quality Intelligence Source

One of the less talked-about benefits of rigorous inspections is the data it generates. When inspection findings are recorded, analyzed, and tied back to suppliers or product lines, it creates a feedback loop for continuous improvement. This can lead to:

Improved supplier evaluation and relationship management

Adjusted sourcing strategies to avoid risky channels

Early warning systems for future component shortages or quality fluctuations

Rather than reacting to customer complaints or returned goods, companies gain the ability to anticipate and eliminate issues upstream.

Building Trust Through Consistent Quality

At its core, every electronics supplier wants the same thing: repeat customers and long-term partnerships. Trust is built not just on pricing or delivery speed, but on the assurance that every part delivered is genuine, functional, and reliable. A high-quality inspection process sends a clear message: "We've checked, so you don't have to worry.”

In an industry where downtime costs money and performance defines brand value, this level of reliability becomes a competitive differentiator.

Conclusion

Incorporating a thorough, risk-based inspection process into your electronic component supply chain is no longer optional—it's essential. Not only does it reduce the tangible costs of return handling and resource waste, but it also strengthens brand trust, operational efficiency, and environmental responsibility.

When quality is verified before shipment, everyone wins—your team, your customer, and the planet.