Scheme introduction:

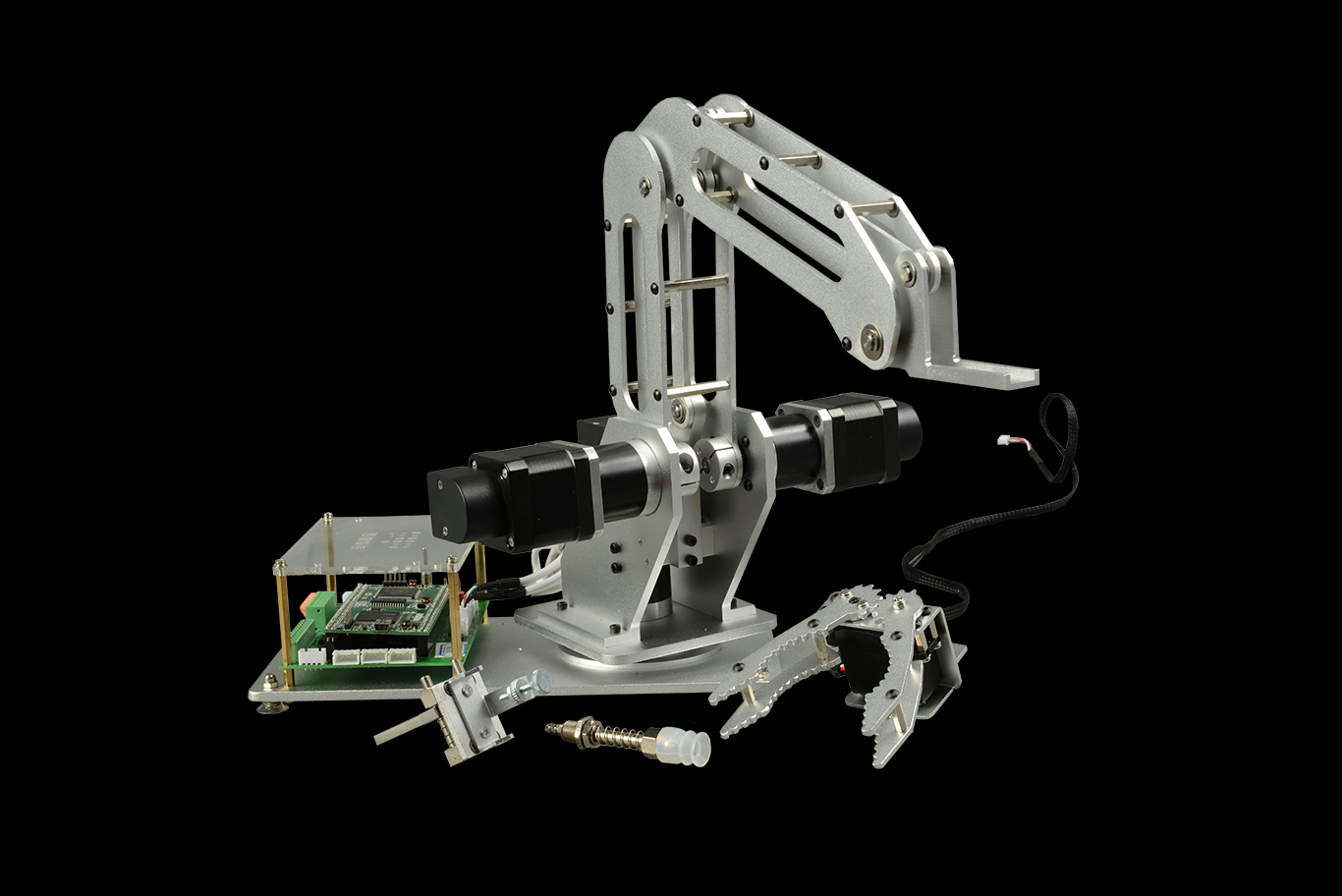

Structure and materials

Aluminum alloy materials plus surface oxidation treatment

Rotating base

3-axis structure

Physical parameters

Mechanical arm size: 160 * 280 * 443mm

The weight of the mechanical arm is about 1.6kg

The weight of the object that can be clamped is about 500g

Hardware parameters

Control chip

Main control chip: STM32F407ZGT6

communication interface

2-channel serial communication interface

2-way steering gear interface

1 channel Bluetooth (CC2540) communication interface

8-channel input signal interface

3-way 42 stepping motor drive interface

7-way drive (500MA) output signal interface

3-channel encoder signal interface

1 channel CAN bus interface

One channel Zigbee (CC2530) communication interface

Core device

24V adapter

3 high-precision bearings (plain bearing 51109, no idle travel)

Three 42 step high-precision reduction motors (42 step motors, step angle 1.8 degrees, accuracy 5%)

Three 500 wire photoelectric encoders

High precision CNC mechanical arm

High precision planetary reducer (length 38.5, reduction ratio 1:13.7, gear rated allowable load 40, gear allowable instantaneous load 60)

Accessories parameters

Steering gear clamping kit (TBSN-K15 flameproof steering gear torque 15KG. cm, alloy mechanical claw)

Writing accessories (with automatic pressure regulator)

Pneumatic suction cup kit (12V voltage, 3W power, air blowing)

Aluminum alloy tool box (50CM * 42CM * 22.5CM)

Experimental support

Basic Experiment

Embedded System Programming Experiment

GPIO experiment

Delay experiment

OLED Experiment

Timer experiment

Stepping motor experiment

Encoder experiment

Basic control of stepping motor

Step motor advanced control I

Step motor advanced control II

Advanced Experiment

Point to point control experiment (writing accessories)

Steering gear test (steering gear clamping kit)

Suction cup test (pneumatic suction cup kit)

Comprehensive Experiment

Manipulator dictation experiment (English dictation, numerical mental calculation)

Performance parameters:

Industry classification: robot/UAV

Development platform: STM STM

Delivery form: PCBA, complete machine

Performance parameters: experiment class hours: 24

Application scenario: college experimental teaching, control learning, step motor learning