In the course of use, electronic products often encounter temperature changes, such as high temperature, low temperature and rapid transition of temperature changes. These temperature changes may have an impact on the performance and reliability of electronic products, so it is necessary to carry out cold and thermal shock testing of electronic products. In this paper, we will introduce the principle of cold and thermal shock of electronic products and standard specifications.

Ⅰ. the principle of thermal shock

Thermal shock testing is a simulation of electronic products in the temperature change under the use of environmental testing methods. In the test, the electronic products will be placed in the high temperature and low temperature environment, or in the high temperature and low temperature between the rapid conversion, in order to simulate the temperature changes in the actual use of electronic products. Through testing, the performance and reliability of electronic products at different temperatures can be understood to provide reference for product design and manufacturing.

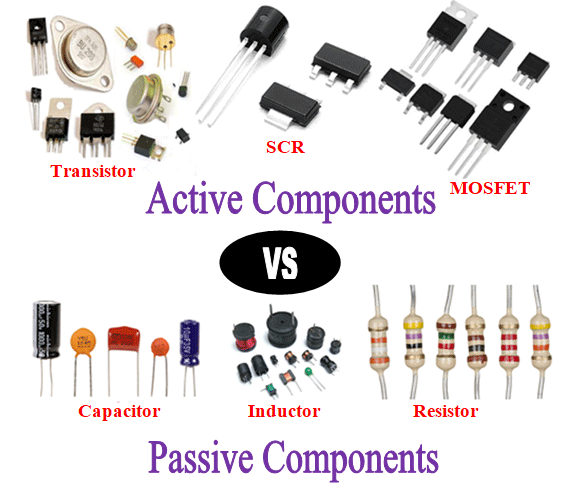

The principle of thermal shock testing is to utilize the physical principle of thermal expansion and contraction. When an electronic product is in a high-temperature environment, the material will expand, while in a low-temperature environment, the material will contract. This change in thermal expansion and contraction may lead to structural deformation, material fatigue, loose soldering and other problems in electronic products. Through the thermal shock testing, the performance and reliability of electronic products under temperature change can be detected, so as to improve the quality and reliability of the products.

Ⅱ. the standard specification

In order to ensure the accuracy and comparability of the thermal shock testing, the international development of a series of standard specifications. The following are common standard specifications for thermal shock testing:

1. MIL-STD-810

MIL-STD-810 is a test standard developed by the U.S. Department of Defense to test the performance and reliability of military equipment in various environments. The standard includes a variety of test methods, including those for temperature changes, such as thermal shock testing and cold shock testing.

2. IEC 60068

IEC 60068 is a test standard developed by the International Electrotechnical Commission (IEC) to test the performance and reliability of electronic products under various environmental conditions. The standard includes a variety of test methods which include temperature change test methods such as thermal shock test and cold shock test.

3. JESD22-A104

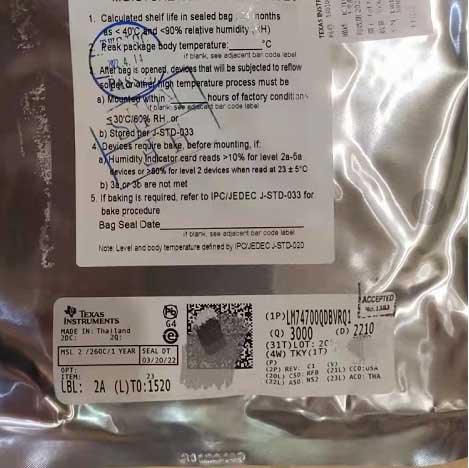

JESD22-A104 is a test standard developed by the Electronic Industries Association of America to test the performance and reliability of electronic products under temperature changes. The standard includes methods and requirements for cold and thermal shock testing, such as test temperature range, test time, and number of tests.

4. GB/T 2423.22

GB/T 2423.22 is a test standard formulated by the Standardization Administration of China for testing the performance and reliability of electronic products under temperature change. The standard includes methods and requirements for cold and thermal shock testing, such as test temperature range, test time, and number of tests.

The above standards and specifications include the methods and requirements of cold and thermal shock testing, which can be used as a reference standard for cold and thermal shock testing of electronic products.

Ⅲ.Purpose

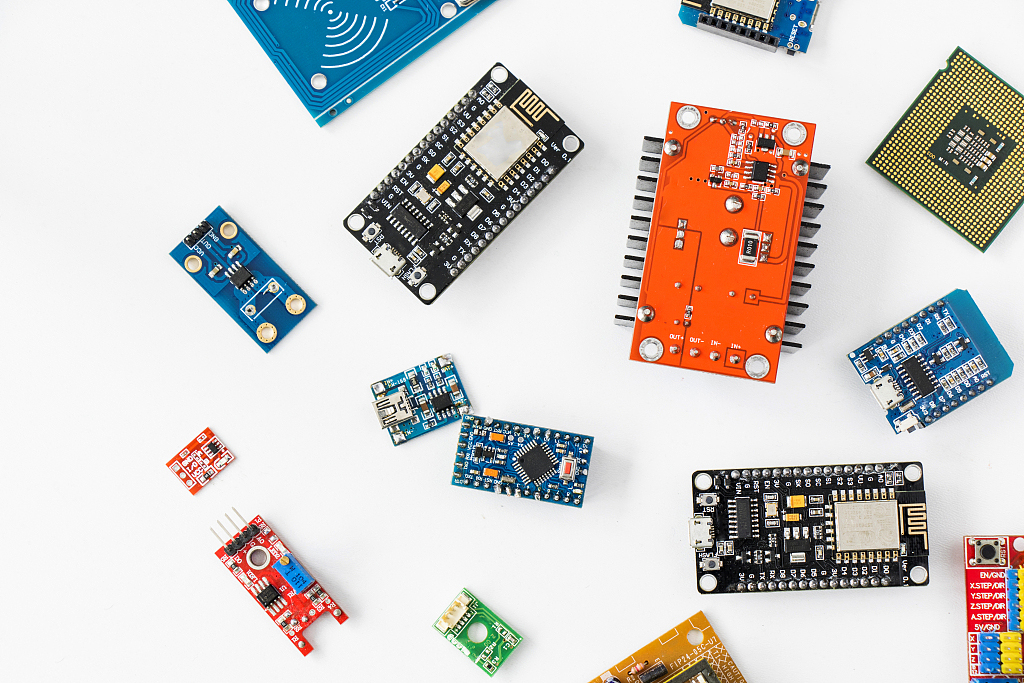

1. Product development stage: timely detection of PCB design defects and correction, so that the design defects stop at the R & D stage, shorten the R & D cycle and reduce costs.

2. Product production stage: test the quality of the product to meet customer requirements, found that the production process defects in a timely manner to investigate the reasons for improvement, to ensure the safety and quality of the products shipped.

3. Material and process certification: Evaluate whether the substrate, ink, PP, process, etc. used meets the reliability of the product.

4. Material and process research: Compare the cold and thermal shock resistance of products with different substrates, inks and processes, and screen good materials and processes.

Thermal shock testing is an important electronic product testing methods, can detect the performance and reliability of electronic products in the temperature change. In testing, standard specifications need to be followed to ensure the accuracy and comparability of the test. Through the thermal shock testing, the quality and reliability of electronic products can be improved to provide reference for product design and manufacturing.

If you like this article, click into perceptive-ic.com to see more.