Before introducing FPC soft board and soft-rigid combination board, let's first understand what is a circuit board?

Circuit boards can be divided into: ceramic circuit boards, alumina ceramic circuit boards, aluminum nitride ceramic circuit boards, circuit boards, PCB boards, aluminum substrates, high-frequency boards, thick copper boards, impedance boards, PCBs, ultra-thin circuit boards , ultra-thin circuit boards, printed (copper etching technology) circuit boards, etc., can be found in any electronic device, and play the role of fixing and connecting electronic devices in the circuit.

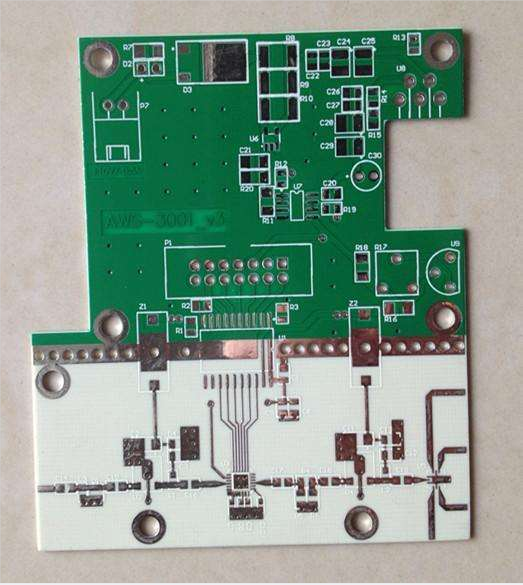

(high frequency board)

(High-power LED aluminum substrate)

(thick copper plate)

(Microwave RF Communication Board)

What is FPC soft board?

FPC circuit board : also known as flexible circuit board, flexible circuit board is a highly reliable and excellent flexible printed circuit board made of polyimide or polyester film as the base material.

It has the characteristics of high wiring density, light weight, thin thickness and good bendability, and is mainly used for connection with other circuit boards.

FPC soft board can save the internal space of electronic products to a certain extent, and make the assembly and processing of products more flexible. For example, LCD/OLED and AMOLED screen display panels in smartphones are connected through FPC flexible boards, which are widely used in notebook computers, digital cameras, as well as medical, automotive, aerospace and other fields.

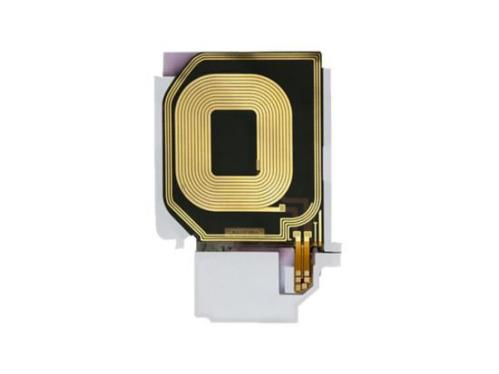

(two-layer coil flexible board)

(four-layer flexible impedance board)

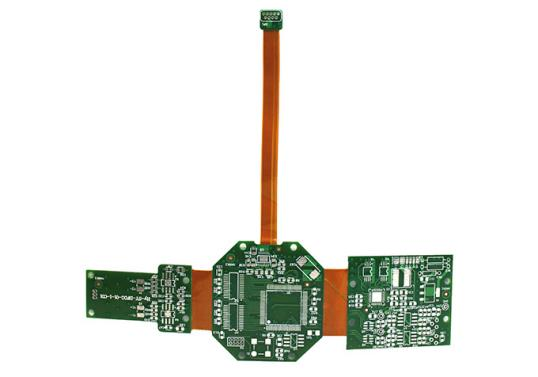

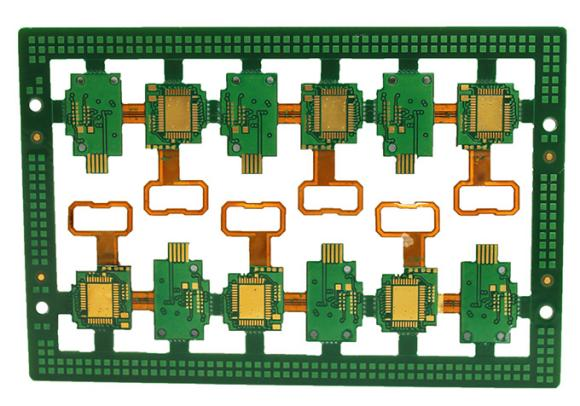

Rigid-flex board : refers to a circuit board with FPC characteristics and PCB characteristics formed by combining flexible circuit boards and rigid circuit boards according to relevant process requirements through lamination and other processes.

The rigid-flex board has both the characteristics of FPC and the characteristics of PCB. Therefore, it can be used in some products with special requirements. It has both a certain flexible area and a certain rigid area, which saves the internal space of the product and reduces the The volume of the finished product is of great help in improving product performance.

However, the production of flexible and rigid boards is difficult and the yield rate is low, so the price is relatively expensive and the production cycle is relatively long.

(soft and hard combination digital image acquisition and processing board)

(4-layer FPC+FR4 soft and hard combination PCB circuit board)

After we understand what is FPC flexible board and flexible-rigid combination board, what do we need to pay attention to in the actual design?

Things to keep in mind when laying out:

1. The device needs to be placed in the hard area, and the flexible area is only used for connection, which can improve the life of the board and ensure the reliability of the board. If the device is placed in the flexible area, it is easy to cause the pad to crack or the characters to fall off.

2. When the device is placed in the hard area, there should be at least a 1mm distance from the soft and hard area.

When wiring, you need to pay attention:

1. The soft area graphics should be at least 10mil away from the edge of the board, no holes should be punched, and the distance between the via and the soft-hard joint should be at least 2mm.

2. The circuit in the soft board area should be smooth, and the corners should be connected by arc wiring. At the same time, the straight line and the arc should be vertical, and the pad should be treated with teardrops to avoid tearing.

3. At the edge of the bending area, copper foil needs to be used to reinforce the connection at the bend of the connection.

4. In order to achieve better flexibility, the bending area should avoid changes in the width of the traces and uneven trace density.

5. The wiring of the bottom layer should be staggered as much as possible to avoid the overlapping of the lines on the bottom layer.