Traditional AC meters are entirely electromechanical. A combination of voltage and current coils is used to induce eddy currents in a rotating aluminum disk. The torque produced on the disc is proportional to the product of the voltage and the current magnetic flux produced by the coil. Finally, a brake magnet was added to the disc, making the rotational speed proportional to the actual power dissipated by the load. At this point, measuring the energy consumed is simply counting the number of rotations over a period of time.

Today's modern AC meters are significantly more sophisticated, accurate, and tamper-resistant. Now, state-of-the-art smart meters can even monitor their absolute accuracy and detect signs of tampering 24/7 when installed in the field. ADI's ADE9153B measurement IC has this function, it uses mSure® technology.

Differences between DC and AC charging piles for electric vehicles

For friends with electric vehicles, the most intuitive feeling is that DC charging is fast (fast charging), and AC charging is slow (slow charging). This is because the batteries of general electric vehicles need to be charged by direct current, and the external alternating current must be converted into direct current in order to be charged.

The more fundamental reason is that DC power can significantly improve efficiency compared to traditional AC power supply. Especially after the emergence of new power switch technologies of materials such as silicon carbide (SiC) and gallium nitride (GaN), the conversion efficiency has been further improved.

DC Energy Metering for Electric Vehicle Charging Pile

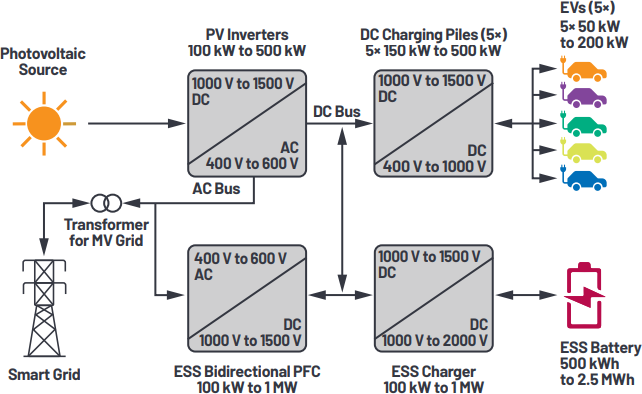

The figure below is a typical electric vehicle charging pile application.

Figure 1: Electric Vehicle Charging Pile Application (Image source: ADI)

The energy source of electric vehicle charging piles can be clean energy (such as photovoltaic power generation) or the grid. Through direct current to direct current (DC-DC) or alternating current to direct current (AC-DC), it is converted into a suitable voltage to charge the electric vehicle.

Some traditional EV charging is metered on the AC side, which has the disadvantage of not being able to measure the energy lost during the AC to DC conversion, leading to inaccurate billing for the end customer.

The best way is to measure both sides of the AC-DC conversion at the same time. The advantage is that through the energy measurement on both sides, we can immediately know whether there is a fault or whether there is a deliberate tamper detection capability.

How to Design a DC Energy Meter

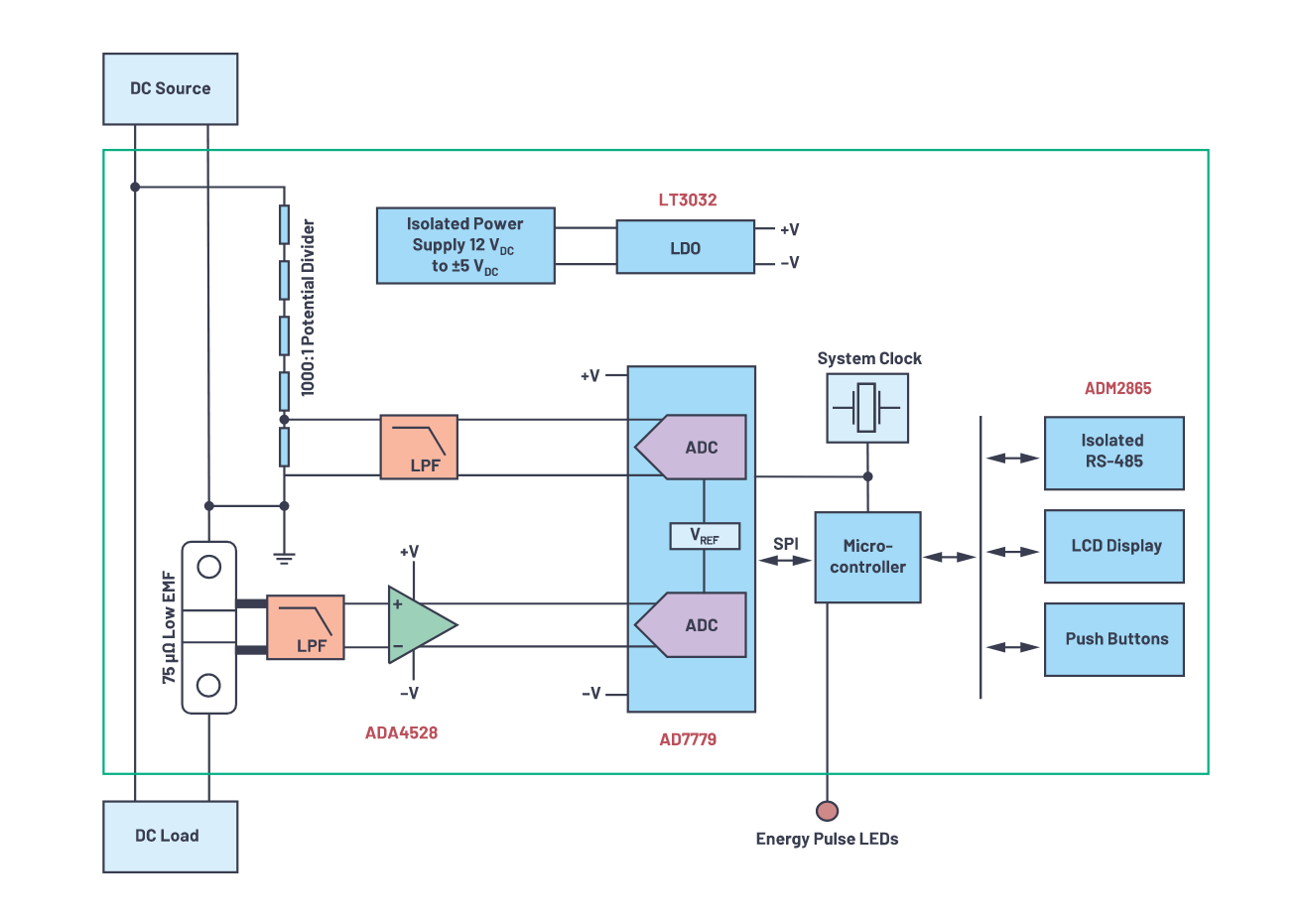

The following is the basic structure of a typical DC energy meter: In order to measure the power consumed by the load (P=V×I), at least one current sensor and one voltage sensor are required.

Figure 2: Basic structure of a DC energy meter (Image source: ADI)

· Voltage Measurement

Resistive Divider: Voltage is often measured with a resistive divider, which is used to scale down the potential to a level compatible with the system ADC input. However, attention must be paid to the temperature and voltage coefficients of the selected components to guarantee the required accuracy over temperature.

For some applications, the corresponding voltage is particularly high, and a high-voltage resistor can be selected at this time.

· Current Measurement

There are two main types of current measurement: direct measurement and indirect measurement.

Direct measurement (based on the current sense resistor): According to Ohm's law, the current passes through a current sense resistor of known resistance, and the current value is accurately calculated by measuring the voltage of the current sense resistor.

This method is economical, accurate and effective, and theoretically has unlimited bandwidth. However, for high current conditions, the current sense resistor heats up severely. This means that when the current is small and the current is large, there will be a large error due to the influence of the temperature coefficient of resistance. Therefore, a current sense resistor with ultra-low temperature drift is required.

Indirect measurement: A magnetic field will be generated around the energized wire, and the current sensor can detect the magnetic field to know the magnitude of the current, thereby realizing indirect measurement.

· Amplifier Selection

Assuming 80A current, the current sense resistor is 75μΩ. The accuracy is required to be 1%, that is, a small signal of 60μV is generated on the current detection resistor, that is, the bias voltage (error) of the amplifier must be at least smaller than this value.

For example, the ADI's ADA4528 has a maximum offset voltage of 2.5 μV and a maximum offset voltage drift of 0.015 μV/°C. Basically can meet the requirements.

It should be noted here that whether it is a current sensor or a voltage dividing resistor, try to use the 4-wire method for measurement, so as to further reduce the influence of the resistance in the cable on the measurement and further improve the accuracy.

· ADC sampling chip selection

For the ADC sampling chip, the 24-bit AD7779 can be directly connected to the amplification stage and has an input bias drift of 5nV/°C.

High DC voltages can be accurately measured through the 1000:1 ratio of the divider resistors and then connected to the AD7779 ADC input.

Finally, connect to the microcontroller MCU to calculate. Instantaneous power (P=I×V), cumulative instantaneous power, is the energy consumed.

Of course, some peripheral devices can be designed and connected later, such as RS-485, LCD display and buttons.